TAWI’s specialised adaptations and configurations of our standard line – our ATEX systems and stainless-steel equipment, for example – allow you to move and handle even the most sensitive or fragile packaging in a safe, secure, and efficient manner.

A process is only as strong as its weakest link

When filling or weighing chemical ingredients or components, it is essential that nothing compromise the packaging or process so as to risk contamination. When trying to increase efficiency in this stage of the process, by reducing manual lifting and manipulation, it is vital that the lifting equipment used does not damage or otherwise risk the integrity of the product or packaging while removing the risk of repetitive strain injuries.

No contamination

TAWI solutions can serve as the cornerstone of a highly safe and accurate filling and weight control system, maintaining the highest hygiene standards and dust control, ensuring maximum product containment, and maximum handling efficiency for any valuable, hazardous or difficult to handle chemical product.

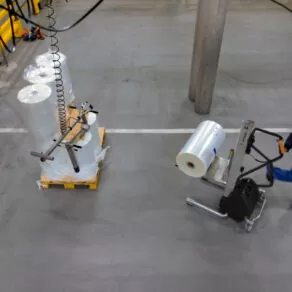

Our vacuum lifting systems offer a wide range of customizable options, are suitable for both drums and sacks or bags, and are designed for high accuracy, ease of use, and maximum flexibility. TAWI solutions can lift, hold, turn, tilt or rotate the raw ingredient containers or packaging, enabling a new level of efficiency, safety, and ease.

Safety for people and product

Lifting strain, explosions, and product contamination are not the only risks. Accidents or faulty handling can lead to chemicals being leaked into the environment – both in the factory and outside. This can have considerable consequences for your operations, from Illness among staff to the loss of brand trust or more. TAWI’s clean room lifting equipment enables operators to lift any load safely and securely, even fragile paper sacks or containers, ensuring that your work environment – and the world around it – is as risk free as possible.

Removing risk before it happens

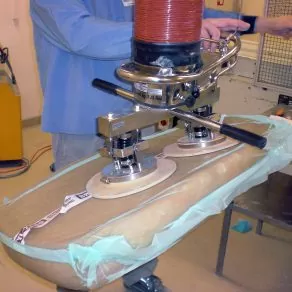

Our vacuum lifting solutions for the chemical industry come in stainless steel configurations especially designed for clean room applications and other controlled environments. Our ergonomic designs provide maximum operator protection and increase production efficiency. Our modular system allows the actual pump device to be placed in another location, which is important in air-locked operations, and allows maximum safety and control even in the most demanding environments.

TAWI clean room lifting equipment feature a hygienic, stainless steel design and offer an efficient, optimized, cost effective clean room lifting solution for any controlled environment where hygiene, handling safety, cGMP’s, and optimum ergonomic efficiency are essential.